Feature Restoration - 1962 Ferrari 250 GTE

Being given the chance to restore cars of any type is both exciting and challenging.

The car owners place their trust in my staff and ultimately with me to give them a car that meets their expectation. A car that they can use and enjoy for many years. A car that could be offered for sale at some time in the future and bring a premium price. This responsibility we take on board and the quality of the work done at every step of the way reflects this.

Such was the challenge when Vern Schuppan brought us the 1962 FERRARI 250 GTE SERIES II.

It had been unregistered for 44 years.

This (RHD) car was delivered new to an official Swiss Ferrari dealer J.H.Keller AG in Zurich, Switzerland. Keller shipped the new car to Australia to an unknown buyer.

Last registered 1974, the Victorian registration number SM013 is still in place on the LH butterfly window.

The first known owner after 1974 was Silvio Massola who had a service station in Hawthorn Rd, East Brighton.

In 1987 Massola sold the car to John Rosar of the Ferrari specialist Pursang Motors. According to Mr Rosar neither he nor Silvio Massola ever registered the car, driving it only occasionally on company trade plates. Vern Schuppan purchased it in 2015, the speedo showed a total of 34,700km.

We have restored several cars for Vern in the past 12 years and this time given the brief, that this one was a keeper, I knew he wanted it perfect or as near to it as humanly possible.

The car looked to be in reasonable nick. The paint was down as you may expect for a car garaged for 44 years, the interior not too bad and the underside was shutzed all over and also looked sound on the hoist.

Even when the paint was removed the true condition was not clear.

There was lead wiping on the panels but no rust visible. Removal of the lead revealed a completely different story. The rust had been cleverly covered with pop rivetted patches and lead wiped all over to hide the sin of a crash repairer with little or no self-respect and certainly none for this fabulous car.

I tend to think that the owner at the time thought he was getting a job befitting his Ferrari but alas not.

The floors had similar treatment. Covered over with new steel sheet riveted on and carefully hidden with bitumen.

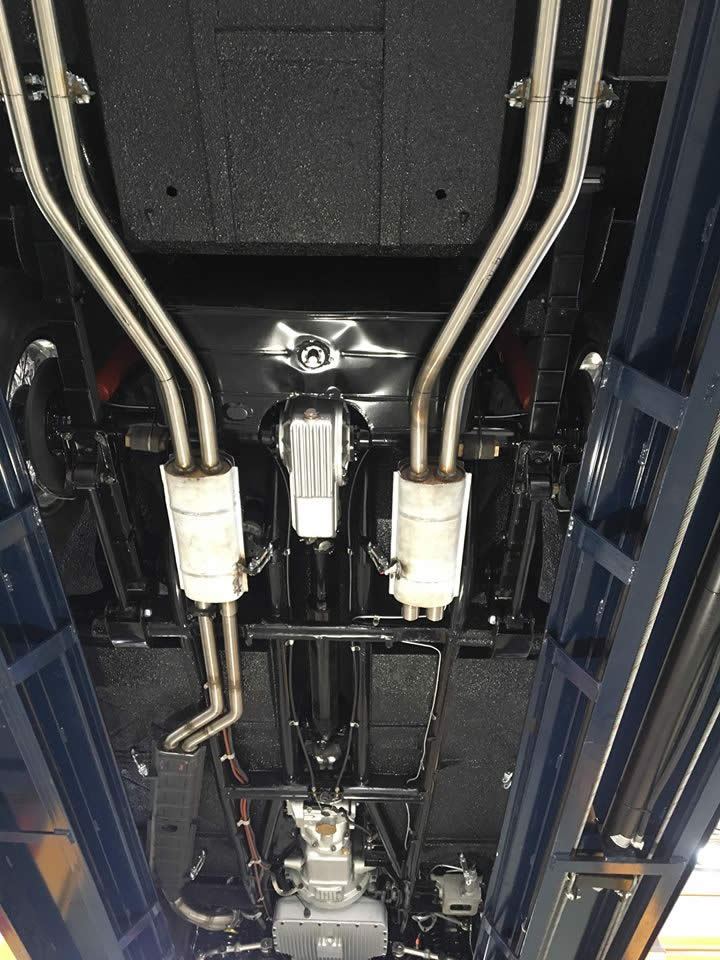

Pininfarina had not painted or even primed any of the surfaces that weren't seen, and this contributed to the damage. The floors have three sheets in the front and two in the rear with footwells 25 mm apart with glass fibre insulation between sheets to help deaden sound and insulate the cabin from exhaust system heat.

Removal of all the patches finally revealed the full scope of the job.

Panels from about knee height down were removed including floors and outriggers from chassis to sills and the box section that included the rear spring hangers. The chassis being for the most part exposed and therefore painted was in great condition.

When all the rust had been removed from the structure and was garnet blasted by Graham's Wingfield Blasting, the chassis needed only epoxy priming to preserve this truly well-designed piece of Italian engineering.

I personally think it could not have been bettered at the time.

The oval drawn tube used to make the main rails is a Ferrari speciality. It cannot be purchased from the makers of the tube or people down the road from Ferrari that hold the supply for the factory. They cannot be swayed!!

The Front cross member is robust to say the least as are the other components of the suspension. Strong, tough, but not truck like. Tough enough to race and take any punishment but light enough to race also.

It's starting to sound like one of those American Resto shows at this stage, but we approached it with the attitude that when finished it should be every bit as good as if it were being done for the launch for the Turin Motor Show in 1962.

Pics taken as the car was dismantled to help with assembly.

The refinishing of the project is trusted to James our team leader in the paint shop. His work, a close inspection shows, is first class.

He has in the past years dedicated his efforts to produce some of the best work in Australia. Not only looking good when the final polish is applied but for years into the future.

The painting process commences with the inner and under of the vehicle being garnet blasted and epoxy chromate two pack applied over the freshly abraded surface. When the outer bodywork is completed with the welding in of patches, they have been painted inside with the same treatment bar the edges where welding is to take place. those areas have weld through primer applied to ensure the longest life possible.

The outer can then be meticulously gone over with an abrasive course sourer on a sander polisher. When the whole car is as shiny as a new pin the chromate epoxy is then applied to freshly prepped panels.

The epoxy it blocks rubbed by hand to rectify any imperfections in shape and form the panels still may have had. the process is repeated till James is satisfied with shape and gaps. Primer filler it sprayed and rubbed to bring it to the next level.

Insides are painted in black semi- gloss to match the cars new finish when it left the factory or in this case as if it were to be shown at its first release of the Series II at the Turin Motor Show in 1962.

Under Frank Portelli's watchful eye the engine and other mechanicals were removed and overhauled as necessary.

Distributors were stripped and kitted as were the Carburettors gaskets and seals replaced on engine,

gearbox and diffs.

Brake system restored completely by sleeving all cylinders and replacing pistons in the callipers replacing seals and rubbers in the booster and all the brake lines both steel and rubber Power Brakes being able to help with all the parts required and we trusted them with overhaul of major components.

Bright work is always a major part of a restoration no more so than on this Ferrari Bumpers, door frames, handles, ashtray, grill surrounds, badges, knock offs, reversing lamp, tail lamp bodies, draft belt moulds, rear view mirror and much more all disassembled, stripped of chrome and returned to us for repair prior to chroming.

Gauges and dials are another challenge on a 250 Ferrari as the heat and sun Down Under is very hard on the Perspex faces.

New faces are not supplied from overseas as they don't seem to have the problem. So, it was up to us to make new replacements.

A die for pressing the new faces to shape was made by Mike from Race Tech Engineering and polished to a chrome like finish. Then Eddy at Acrylic Art computer cut and etched the faces from acrylic. Then off to City Plastics to have the acrylic heated to just the right temp. for forming in the die. That done only need to paint in the numbers and letters on all eight dials.

The result is worth all the effort.

As always, we trusted Allen from Allen Smith vehicle trimming for the interior and with the utmost care the trim was completed as it would have been from the factory.

Assembly on a vehicle like this is more work than many cars of its time due to the detail and refinement built into a Ferrari. It is again a part of the car that cannot be taken lightly. And it is where each of the staff take the task seriously. Frank and Trevor with Nick's help look after the mechanical. Tirama, Cameron and I have a hand in the body windows doors new dash Gauges with help from Michael, Mark and James and Ashley attending to paint details after and during assembly. Nick and Aaron doing great work on the exhaust system and Armando helping with the finishing touches.

None of this would happen without the organizational skills of Lesley the Manager.

The 250 GTE Ferrari is a joy to drive and can only be appreciated by those who have been lucky enough to have driven The Great Ocean Road or the like in one of these cars that was a long-time favourite and daily drive of Enzo himself.